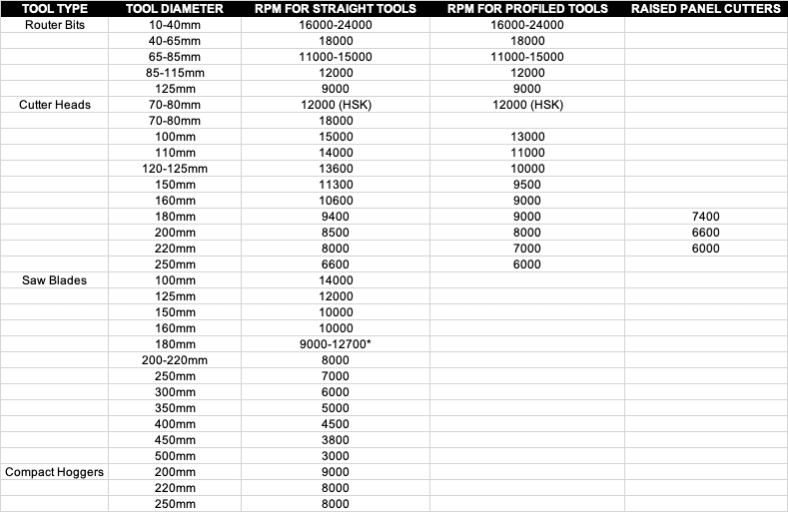

What is the rpm for a specific tool diameter?

This depends on the type of tool and whether it’s a straight cutter or a profile tool. Below is the typical range:

***

How can one identify ER style collet size?

The quickest way is to measure its overall length. Each ER style collet has a unique overall length as follows:

| ER Style | Length |

| ER8 | 13mm |

| ER11 | 18mm |

| ER16 | 27.5mm |

| ER20 | 31.5mm |

| ER25 | 34mm |

| ER32 | 40mm |

| ER40 | 46mm |

| ER50 | 60mm |

Can You Use an End Mill or Router Bit to Drill a Hole?

It depends on the application. For example, a 2″ diameter hole in a 3/4″ panel can be created by routing with a 1/4″ router bit. However, this can generate excessive heat, potentially causing burning, due to slower feed rates. Drilling a 1/2″ hole with a 1/2″ router bit isn’t possible because router bits (or end mills) are not designed for drilling; they need horizontal movement to remove chips efficiently. Unlike drill bits, router bits are prone to burning or breaking when used for drilling tasks.

***

What are the correct parameters (feeds and speeds) for drill bits?

The sweet spot for drill bits will fall in the ranges below based on production needs.

3000 rpm 1-2 meters (40-80” min)

4500 rpm 1.5-2.5 meters (60-100” min)

6000 rpm 2-3.5 meters (80-140” min)

9000 rpm 2.5-5.5 meters (100-220” min)

***

What is Chip Load?

“Chip load” measures the size of the chip removed by each flute or cutting edge during the cutting process. This calculation depends on the tool’s rotation speed (RPM), feed rate, and the number of flutes on the tool. The formula for chip load is:

Chip Load = Feed Rate (inches per minute) / (RPM x Number of Flutes)

Accurate chip load helps maximize tool life, improve cutting efficiency, and ensure a smooth finish.

***

Why is Correct Chip Load Important?

The correct chip load is essential for optimal cutting performance and tool longevity. Determining the proper chip load requires considering the material, tool diameter, depth of cut, number of flutes, spindle RPM, and feed rate. Incorrect chip load can lead to excessive heat, tool breakage, and poor surface finish. Proper chip load maximizes tool life and enhances finish quality. For precise calculations, use our chip load calculator.

***

How to Find Your Optimum Chip Load

To determine the optimum chip load, start with the recommended chip load range and gradually increase the feed rate until finish quality drops. Then, reduce the feed rate until the desired finish is restored and note the feed rate. Next, slowly decrease the machine RPM until finish quality deteriorates, then increase the RPM until the finish improves. This process reveals the “sweet spot” for your specific setup, ensuring maximum tool efficiency and finish quality.

***

Easy Way to Remember Chip Load

Think of chip load like Goldilocks: too large a chip load reduces finish quality, while too small a chip load shortens tool life. The goal is to find the “just right” balance—where chip size ensures both a smooth finish and optimal tool longevity.

***

What are cutting tool safety standards?

The American National Standards Institute has not developed a comprehensive safety standard for industrial cutting tools. Europe has extensive safety and production standards to ensure that cutting tools are designed to the highest precision and adhere to the strictest safety regulations. (DIN – German Institute for Norms).

***

Is All Tool Holder Quality the Same?

No, tool holder quality varies significantly and impacts machining performance. A tool holder connects the spindle and tool; if unbalanced, it can cause oscillation (chatter), leading to costly spindle damage, runout, and premature wear. Choosing a reputable supplier reduces these risks. Some tool holders come with static collet nuts, which are lower-cost, lower-quality, and less accurate compared to ball bearing collet nuts. A ball bearing collet nut supports both clockwise and counterclockwise rotation, while a static collet nut limits rotation to right-hand tools unless it’s a dedicated left-hand holder.

***

Which type of tool holder should I use?

For general use, a standard collet chuck is more than adequate. Depending on tool holder/collet quality and age, the tool concentricity is generally in the .006-.010mm range. If vibration is evident in the cut, despite a new collet and a bearing nut, a high precision chuck is recommended. An alternative, that offers higher clamping force and accuracy, is a higher cost hydro chuck. For best performance of both PCD and insert tools, and a runout of maximum .003mm, a heat shrink chuck is the best and most cost-effective choice. It can increase tool life up to 30% and eliminates the cost of replacement collets. Insert tools will never have to be removed from their holder and PCD tools can be sent for service on the holder.

***

How Long Do Collets Last?

Collets should be replaced every 500 machine hours to maintain optimal CNC performance. Worn collets can lead to spindle damage, tool chatter, breakage, vibration, run-out, and reduced tool efficiency. Regular collet replacement is crucial for preventing costly machine issues and ensuring high-quality output.

***

What is the proper way to assemble a tool?

First snap the collet into the collet or cyclone nut. Then place the tool into the collet, tighten the collet manually onto the tool holder. Next, position and secure the tool holder in a tool setup fixture. Finally tighten collet nut with a torque wrench. View demo here.

***

What is the proper torque to tighten a collet nut to?

The amount of torque depends on collet style being used.

For ER 20 torque = 59ft/lbs.

For ER 32 torque = 100 ft/lbs.

For ER 40 torque = 130 ft/lbs.

For RDO 35 (SYOZ25) torque = 90 ft/lbs.

***

How to Properly Tighten a Collet Nut with a Torque Wrench

To properly tighten a collet nut, secure the tool holder in a tool setup fixture. Then, use a torque wrench to tighten the collet nut to the specified torque for safe and accurate performance. When removing the tool from the collet nut, avoid using the torque wrench, as this can compromise its accuracy.

***

Dust seems to bog down my tool when its cutting, how can I avoid this? If dust collection system is performing inadequately, consider repositioning and assisting faster chip evacuation by replacing the standard tool holder collet nut with a Cyclone Dust Nut. The best results are obtained using tools with the shortest cutting length possible for the application needs.

***

How to Fix Oval or Out-of-Round Holes on a CNC Machine

If your CNC machine is producing oval or out-of-round holes, the issue may stem from using standard metric drill bits with flat-edged shanks. These flat edges can cause improper mounting in the collet, leading to inaccurate drilling. To solve this, use a drill bit adapter with a 10mm cylindrical shank (without a flat edge) that fits into the 10mm collet. This adapter has a female end that accepts the 10mm drill shank with a flat edge and secures it with a set screw, ensuring precise alignment and round holes.

***

What drill bit do I use for blind or through holes?

A “Through Hole Bit”, also referred to as “V-Point” is for holes that are meant to go all the way through material and exit the other side. A “Dowel/Brad Point” is used for holes that are intended for blind holes, i.e. they stop at some point in the material. A “Hinge Boring Bit” as the name suggests is the best option for hinge pockets and hardware recess holes.

***

Is there an adapter for many different drill diameters and can’t find collet size needed?

A Universal Drill Adapter is the best and only option for efficient and consistent drilling operations where collet sizes for the drill shank are not readily available.

***

How to Choose a Router Bit for the Best Finish

When selecting a router bit for a quality finish, consider more than just the number of flutes. Although additional flutes can support a faster feed rate, they don’t necessarily improve finish quality. Achieving the best finish depends on balancing feed rate, RPM, and chip load.

Remember, more flutes require faster feeding. Feeding too slowly with more flutes can cause premature tool wear and excess heat. For optimal results, choose a bit based on your material and machining parameters, not just flute count.

***

What is a good router bit for cutting flexible plastics?

A solid carbide O-Flute bit, which has a concave radius flute shape, is equipped with geometry that is ideal for cutting flexible plastics.

***

When I am machining laminated material face down what bit should I use?

The ideal bit for machining laminate facedown is an UPCUT spiral bit. Unfortunately though, this could yiel the potential to chip or fray the bottom side of the material which is on top when machining face down. The other alternative is a compression bit.

***

Is there a tool the can effectively cut complex, irregular surface shapes?

A Ball Nose UPCUT bit would be an excellent choice. Its rounded shape will provide seamless passes as the tool moves across the material in multiple passes.

***

What tool can provide high quality top edge finish?

A downcut bit provides superb top edge finish. This bit has the potential to push chips down into the cut. However, if matched with proper dust extraction this shouldn’t be an issue.

***

What are some good tips to remember to get the most out of my tools?

- Always adapt the cutting length of the router tool to the panel thickness, i.e. cutting length should be minimally longer than the panel thickness.

- Always choose the stronger tool, i.e. cut length not too long and diameter not too small.

- Material hold-down must fit the tool. That means, select small diameter tools for thin panels or parts that are prone to moving

- Chip clearance is better on larger diameter tools, therefore when running high feed rates and thicker panels, use a diameter of 5/8” or greater diameter.

- Select highest accuracy clamping tools. (precision collet chuck, Heat shrink, Hydro Chuck or Preziso)

- If using collet chucks, replace collets regularly. (every 500 machine hours!)

***

Should I use carbide or diamond on MDF and Particle board?

For heavy use, due to the introduction of 2 flute PCD in diameter 3/8 or ½, we recommend using PCD tooling to decrease tooling cost providing homogeneous material is being cut. A PCD bit for all purpose machining is generally not recommended. For best results, diamond tools should be ordered on an HSK heat shrink toolholder.

***

When Not to Use PCD Tooling

Avoid using PCD tooling in these situations:

- Material type and thickness vary, and dedicated diamond tools for each operation aren’t practical.

- High upfront costs pose a challenge, even though PCD tools save money over time.

- The material may contain staples, nails, or other hard inclusions that can damage PCD tools.

- The machine has excessive spindle runout, or parts shift on the table—stick with carbide in these cases.

- Machine operators lack proper handling discipline, as PCD tools require careful handling.

- Investment in a full setup, such as new collets or a heat shrink tool holder, isn’t feasible.

- Parts require direct plunge cuts into material, which can cause heat buildup and premature PCD wear.

***

How do I calculate chip load?

Chip load = Feed Rate(in/min) / (RPM x # flutes)

***

What is the best tool for recessed cuts and surface planing (for instance, shaker doors) ?

Our FOURCUT surface planer is ideal for this application. It can produce high quality surface finish and is an excellent choice for making MDF shaker doors, for instance.

***

If I need to cut deep into material what is the best option to avoid tool breakage?

Considering the rule of thumb is that cut length shouldn’t exceed three times the cut diameter, that means that cutting a deep mortise pocket can represent a challenge. Special deep pocket mortise bits solve that problem as they are made from a very special high-density alloy that prevents deflection and tool breakage despite the depth of cut. A multi-pass progression is required.

***

If I need to cut mitre folds, what tool should I use?

A V-Groove bit is available for this application. They can be found in 45, 60, 90 and 91 degree folds with special angles on request. Fortunately, the inserts are double sided giving longer cutting life. Special angles can be made as needed.

***

What is the process to order a custom tool?

The process is very simple. A profile drawing or material sample is supplied in order to obtain a firm price quote. Then, once an order is placed, a dimensioned drawing is submitted for review and approval or revision. After final approval takes place then manufacturing begins and is wrapped up usually within 4 weeks or sooner!

***

Cost-Effective Solution for Short Runs or Small Projects

For prototype production and one-off projects, a corrugated knife adapter with a heat shrink tool holder is an affordable and flexible choice. This steel-bodied tool accepts 8mm, 5/16”, or 1/4” x 60-degree corrugated knives, compatible with 40, 60, and 80mm knife lengths. Unlike similar aluminum-bodied cutters, which can wear down and become hazardous, the steel construction ensures durability and safety. This cost-effective solution is ideal for short runs without compromising performance or safety.

***

If I want to run a saw blade on my CNC what sizes of blades should I use?

For saw blades up to 200mm we recommend a shank-style adapter. For saw blades up to 400 mm the clamping flange style adapter is necessary. For blades up to 350 mm we have a standard flange assembly.

***

What is the benefit of a tool setup fixture?

Accurate tool set up will save much time, and improve tool accuracy. This is imperative to save setup time and reduce waste.

***

What are the benefits of utilizing an aggregate head?

Aggregate heads can yield many benefits depending on the head equipped. Boring, sawing, in both horizontal and vertical directions are possible. Along with having from one to four outputs, maximizing efficiency.

***

How can I protect my spindle motor from dust intrusion?

When the machine is not in use or being moved, HSK spindle plugs prevent dust and debris from getting into the spindle. In addition, some machinery companies theorize that dust can actually enter the spindle but getting sucked into it through the collet/collet nut pathway. While this is unlikely, there are small plugs available that allow closing off the small center hole in the HSK which is standard on all HSK tool holders.

***

What does it mean if my tools have collet marks on the tool shank?

This is a sign that there is unwanted vibration in the cutting process. This is typically caused by a worn-out collet, incorrect torque, low quality tool holder, insufficient tool shank buried in the collet.

***

Is there a way to verify that spindle is accuracy?

Using a test calibration bar can make the identification of spindle problems fairly easy. This is an important maintenance step in order to prevent costly spindle repairs.

***

Why Do CNC Tools Break?

Tool breakage often results from one or a combination of these factors:

- Worn or damaged collet

- Poor quality tool holder or collet nut

- Incorrect torque settings

- Excessive vibration during cutting

- Tool clamped too high on the shank

- Shallow cut depth relative to the tool’s cutting length

- Excessive heat from incorrect chip load or running a dull tool

Addressing these issues can improve tool life and prevent unexpected breakage.

***

What does it mean if the bit appears to be burned or is discolored?

This is typically due to improper chip load (chip load is too small), which can greatly reduce tool life. This means machining parameters need to be modified, i.e. that RPM, feed speed or number of flutes needs to be changed on the cutting process.

***

If I need to remove a lot of material in a cut quickly what is the best tooling option?

A rougher is the tool for that job, but if good surface quality is needed, a second pass with another tool is necessary.

***

What tool should I use for cutting plywood and OSB panels with a good surface finish? A Compression Chip Breaker is the best bit for that job. The chip breaker facilitates getting bulky chips reduced and out of the cut to provide a cooler running tool and longer tool life.

***

What is an ideal tool for cutting material that has a laminate or coating on both sides?

A compression bit would be the solution for cutting this material. The geometry of this tool, two opposite shear angles, causes the tool to cut towards the center of the material. This leaves excellent quality on top and bottom of material.

***

What is a good router bit for cutting rigid plastic materials?

A solid carbide O-Flute UPCUT bit is ideal for rigid plastics such as: Acrylics, Nylons, Plexiglass and others.

***

When does purchasing PCD tooling become an economical choice?

PCD tooling is the extremely economical when it is dedicated to cutting homogenous material of the same thickness and not exchanged between material types, for example switching from composite to wood.

***

Why should I purchase a Tool Setup Fixture and Torque wrench if a can assemble my tools without either one?

To avoid tool breakage and achieve optimum tool life, investing in a tool setup fixture and torque wrench definitely have their benefits! It allows tool holder setup to flow seamlessly, eliminates the guesswork of correct torque and tool alignment during assembly. This ensures accuracy during the cut and best possible performance of the tool.

***

Why should I choose a Bearing Nut over a Static Nut?

The Ball Bearing Nut allows the ability to run CCW and CW tools as well as offering a higher clamping force improving both accuracy and finish.

Why is My Router Bit Slipping Out of the Tool Holder?

Router bit slippage typically occurs due to the following main issues:

- The collet nut isn’t tightened to the correct torque specifications.

- The collet nut lacks a bearing, which reduces clamping force.

- Tool shank is undersized or incorrect collet diameter being used. (example: Using 1/2″ (12,7mm) collet for 12mm tool shank).

Ensuring the correct torque and using a collet nut with a bearing can help prevent bit slippage.

***