Cutting HPL and Phenolic Panels

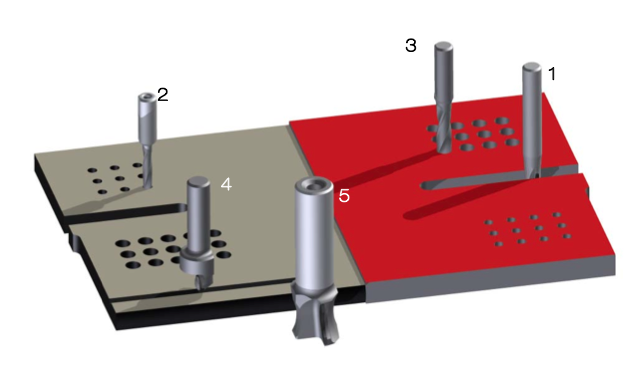

High pressure laminates (HPL) and phenolic panels are becoming more popular due to durability and performance properties including chemical, fire and wear resistance. Furniture, floors, cabinetry and countertops are just a few of the products that utilize HPL and phenolic materials in modern designs. Cutting composites can be challenging and the characteristics of material composition should dictate your tool type, feed speed and spindle RPM. When cutting HPL and phenolic based composites, chip out and tool life are both potential pitfalls as illustrated in this woodweb.com post. Many composites will destroy solid carbide tools due to the abrasive nature of the material. Here are examples of the diamond tooling we suggest at GDP to cut HPL (left) and Phenolic (right) composite panels.

1 DIATEC-4 Diamond Router Cutter

2 DIAMOND-Dowel Drill

3 DIAMOND Dowel Drill

4 FOURCUT Diamond Decorative Groove Cutter

5 Diamond Rounding Cutter

Be sure to wear a respirator/utilize dust collection equipment as the panels produce fine dust when cut, which can be detrimental to health!

For specific projects or machining challenges, we would love to provide the solution for you. Contact us at 800-544-8436 or email us at sales@gdptooling.com