Disposable Inserts Help Reduce Machine Downtime

Disposable inserts can reduce grinding costs and minimize machining downtime. The evolution of cutting tools has progressed from being quite labor-intense to heavily relying on machines and automated processes. With these efficiencies, it is now more important than ever to keep down set-up times and adjustment times in order to minimize tooling related costs.

The introduction of CNC machines (vertical CNC routers, automated panel processing systems) over the last +20 years have made a massive impact on the millwork and woodworking industries as well as many others. One of the problems with the structural shift to CNC machines was that all traditional tools, like carbide tipped cutters, change dimensions after being sharpened. Router bits, drill bits, and boring bits become shorter, and shaper cutters lose diameter and profile detail. With the development of CNC machines, the industry was in need for precise cutting tools that wouldn’t change dimensions once they had to be sharpened. This demand became first apparent in Europe, leading to the development of disposable insert knives made of solid tungsten carbide. The knives were developed to provide constant diameter at a lower cost to complement CNC machines.

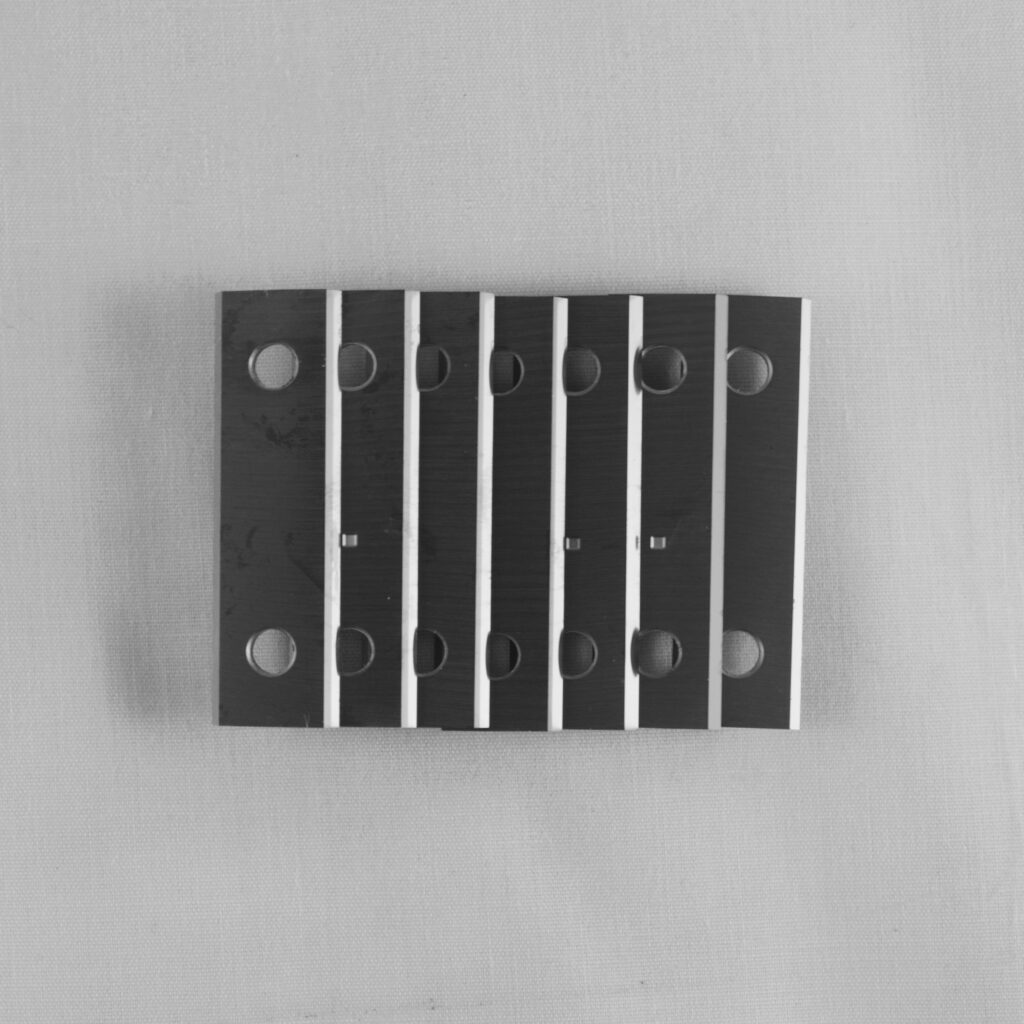

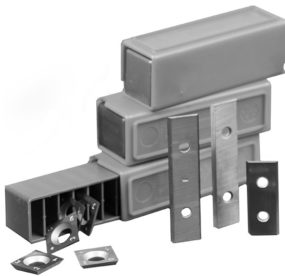

The main advantage initially in this type of tooling lies in the fact that the knives are made of tungsten carbide alloy. Tungsten carbide tooling is harder than most other brazed-up type cutters providing a longer tool life as well as a constant cutting diameter. Insert knives are CNC compatible and with the ability to quickly replace them, they reduce machine downtime.

Another advantage lies in the insert clamping devices and wedges. The holding devices are designed to conform to multiple performance parameters that deal primarily with the workload placed on them and the applicable safety characteristics. As fail-proof as possible, the clamping devices are designed in a way that the wedges are inverted, leading to centrifugal force tightening. Additionally, the wedges also serve as chip removal gullets and chip breakers.

The workload capacity of disposable insert tools is generally less than that of traditional massive cutters tipped with either high-speed steel or tungsten carbide. The difference, though, is negligible since the achievable feed rates for most applications are still more than sufficient. A jointing cut feed rate of 15 feet per minute, for example, is easily reached and should be adequate for most situations.

Please contact us for more information on how inserts can reduce your tooling related downtime.