Machining Bead Board Profiles

If producing bead board is part of your product offering, there are several options to achieve this profile. The preferred option with grooving capability is using a profile insert or PCD (polycrystalline diamond) cutter head. It is the most efficient and cost effective solution, allowing the bead board profile to be cut in a single pass, without tear-out. If you’re using this on a table saw for instance, the cutter body would be produced of light weight aluminum to keep the weight of the tool to a minimum reducing wear on the machine.

Some bead board profiles can also be made as a custom saw blade, which incorporates the bead board profile and can be run on a table saw. (see illustration below).

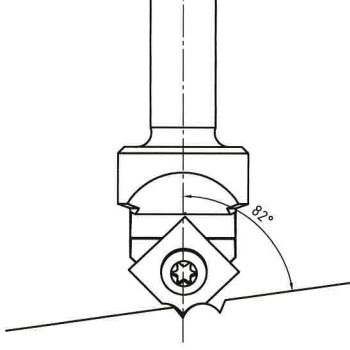

Another option, if only smaller quantities of a conventional bead board (profile as shown below) are produced, requires either a 5-axis CNC machine or a variable angle aggregate head to accomplish the task. This method is more time consuming and only advisable for small runs because it requires 4 passes to complete the profile. It also requires either the tool to be on a spindle tilt, or the material to be on an angle while being machined. The tool on the left is a V-Groove tool used to complete the two outside grooves in two passes, while the tool on the right completes the inside “bead” profile in two passes. Whether using a profile cutter head or router tools, both options will provide an excellent, paintable finish.

Finally, of course it is easy to produce a modified bead board profile with any router that can be machined in just two passes . However, it requires the outside edge of the bead profile to have a radius as well. (i.e. another radius, mirroring the center radius will make up the outside edge of the bead and the angle will be eliminated.)

For solutions on bead board, folding, engraving and decorative profiles or any other specialty project, contact us so we can reduce your total cost of tooling and guide you to the most appropriate tool for the job.