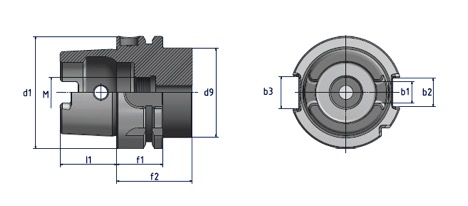

If you are ever tasked with the challenge of identifying an HSK tool holder interface, the following will guide you through the differences and dimensions of the machine spindle interface (upper portion) of the HSK holder. These high-precision clamping tools are available in several configurations, including heat shrink construction, collet chucks, Weldon shank adapters, and arbor adapter options. Additionally, other unique features can include internal coolant tubes, Balluff chip accommodation, slimline designs, and long-reach models, among other attributes. Furthermore, the HSK tool clamping systems are classified by universal DIN standards (German industry norm classification) and come in various sizes and dimensions. Here’s how to identify the most common ones below.

DIN 68893-1 includes HSK-A 63, HSK-A 80, HSK-A 100, HSK-A 40 and HSK-A 50

| HSK-A | d1 | d9 max. | l1 | f1 | f2 min. | b1 | b2 | b3 | M |

|---|---|---|---|---|---|---|---|---|---|

| 40 | 40 | 34 | 20 | 20 | 35 | 8,05 | 9 | 11 | M12x1 |

| 50 | 59 | 42 | 25 | 26 | 42 | 10,54 | 12 | 14 | M16x1 |

| 63 | 63 | 53 | 32 | 26 | 42 | 12,54 | 16 | 18 | M18x1 |

| 80 | 80 | 68 | 40 | 26 | 42 | 16,04 | 18 | 20 | M20x1,5 |

| 100 | 100 | 85 | 50 | 29 | 45 | 20,02 | 20 | 22 | M24x1,5 |

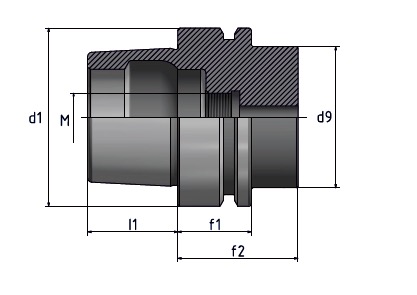

DIN 69893-5 includes HSK-E32, HSK-E 40 and HSK-E 50

| HSK-E | d1 | d9 max. | l1 | f1 | f2 min. | M |

|---|---|---|---|---|---|---|

| 32 | 32 | 26 | 16 | 20 | 35 | M10x1 |

| 40 | 40 | 34 | 20 | 20 | 35 | M12x1 |

| 50 | 50 | 42 | 25 | 26 | 42 | M16x1 |

DIN 69893-6 includes HSK-F 63

| HSK-F | d1 | d9 max. | l1 | f1 | f2 min. |

|---|---|---|---|---|---|

| 63 | 63 | 53 | 25 | 26 | 42 |

Got an upcoming requirement? Our tool clamping systems are made to the highest quality standards and manufactured in Germany. Standard sizes available from factory stock! Contact us for price and lead time!