Cutting Particleboard with Rough Cut Veneer or Stainless Steel Laminate

When it comes to cutting tools for particleboard, there is no “one-size-fits-all” recommendation. When machining particleboard (an engineered wood product) it is imperative to make the correct tool choice if obtaining optimal tool life is desired. Tool wear rate will much depend on the composition of the particleboard itself. Depending on the mill it came from, the type of wood species predominant in the composition of the board, the resin and other binders used will all impact tool life. This explains why after changing particleboard suppliers, one might expect either better or worse tool performance. In addition, depending on the surface coating of the panel, whether melamine, high pressure laminate, veneer, paper, it will also affect the tool life / performance. Have an upcoming project? Let’s talk! Contact us at your convenience! Below are some examples of our solutions:

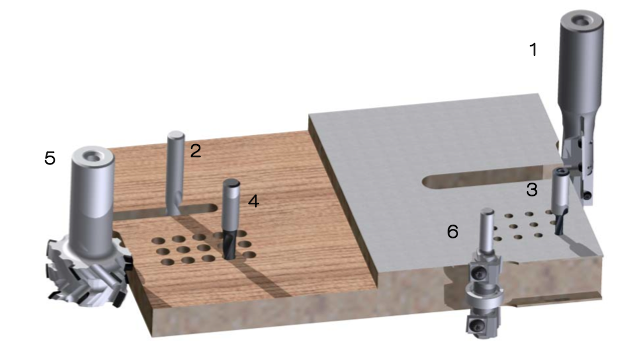

Workpiece left: Particleboard with rough cut veneer

Workpiece right: Particleboard with stainless-steel cover

(Similar materials: Particleboard with magnetic foil etc.)

1 Cutter with rev. T.C. tips Z2+2 No. 22029-5

2 Solid T.C. cutter with alternate shear angle Z2+2 No. 20252-6

3 ISODUR Dowel Drill T.C.T. Z2 No. 30570-5

4 Dowel Drill T.C.T. Z2 No. 30540-5

5 MEGASPEED Diamond Router Cutter Z4+2+4 No. 15600-9

6 Double Edge Trimming Cutter w. rev. T.C. tips Z2 No. 22293-5

For more information visit our website at www.gdptooling.com