PCD Diamond Router Bits: Engineered for Performance and Cost Savings

PCD (polycrystalline diamond) router bits are a premium tooling solution for high-volume production environments and abrasive materials. Designed for exceptional wear resistance, these tools can offer dramatic cost savings and consistently high-quality cuts in the right application — particularly when cutting wood-based composites, laminated panels, MDF, particleboard, and thermoplastics that are free of metal inclusions or other contaminants.

Recently highlighted by woodworkingnetwork.com in an article on advanced tooling technologies, PCD router bits are recognized for their long tool life, sharpenability, and precision cutting, making them an ideal choice for manufacturers looking to reduce downtime, extend tool change intervals, and improve edge quality.

Featured PCD Router Bit Models

6811 – Disposable-Style Single Flute Diamond Compression Bit (Z1=1)

This tool is designed for lower feed rate applications up to 18 ft/min, offering a 1″ cut length. While considered a disposable bit, it can be resharpened once, extending its life and improving cost efficiency compared to solid carbide tools in similar applications. Ideal for short-run nested-based manufacturing where precision is critical but throughput is lower.

6812 – 2-Flute Diamond Compression Router Bit

Featuring a solid carbide tool body with a short upcut, this bit is optimized for nesting operations on laminated or composite materials. The compression geometry shears fibers inward from both surfaces, delivering a clean edge finish on both the top and bottom of the panel. Under normal wear conditions, it can be resharpened up to four times and supports feed rates up to 650 IPM.

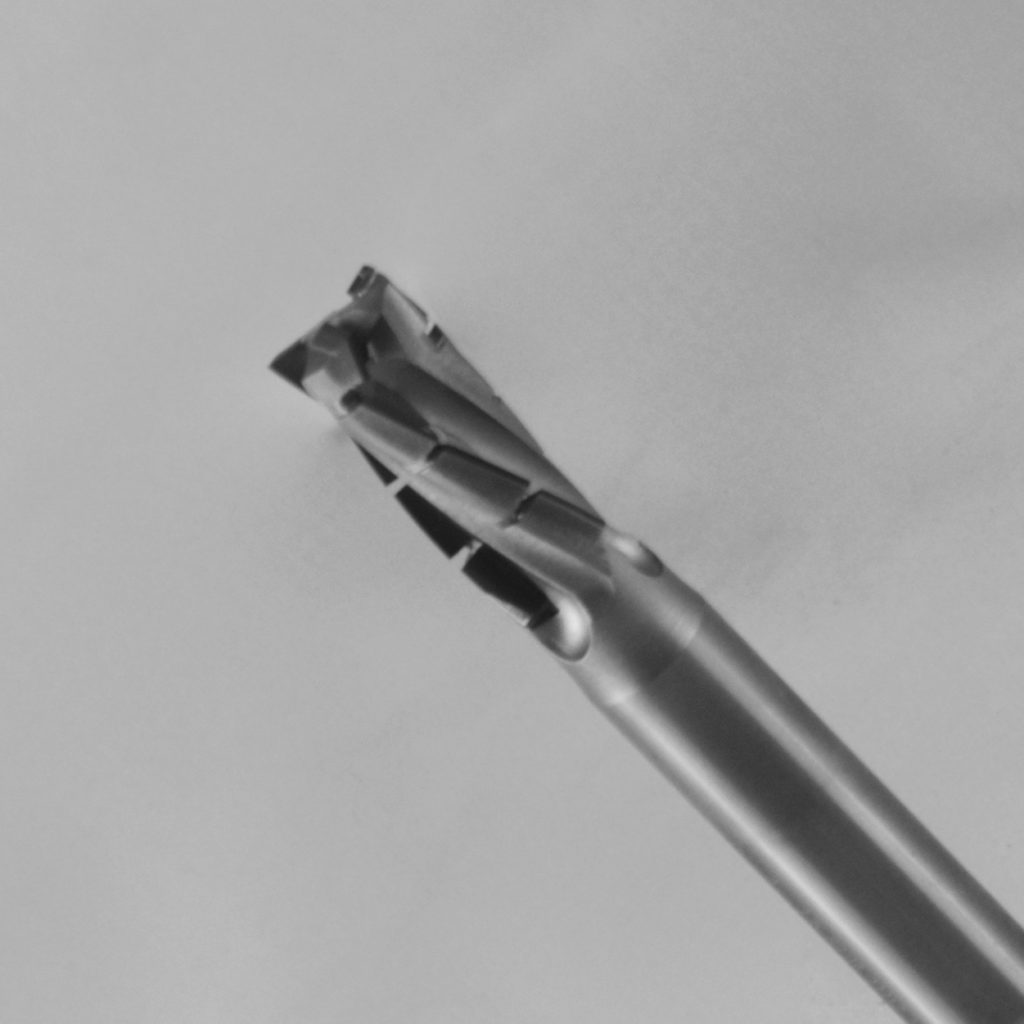

6818 – 3-Flute Diamond Compression Router Bit

Building on the 2-flute design, this version adds a third flute, increasing the tool’s ability to handle higher feed rates — up to 900 IPM. Like the 6812, it uses a solid carbide tool body and compression shear design for clean edge quality in laminated materials. With up to four sharpenings, it offers long-term value in high-speed CNC environments where throughput is a priority.

For more information visit our website at www.gdptooling.com